|

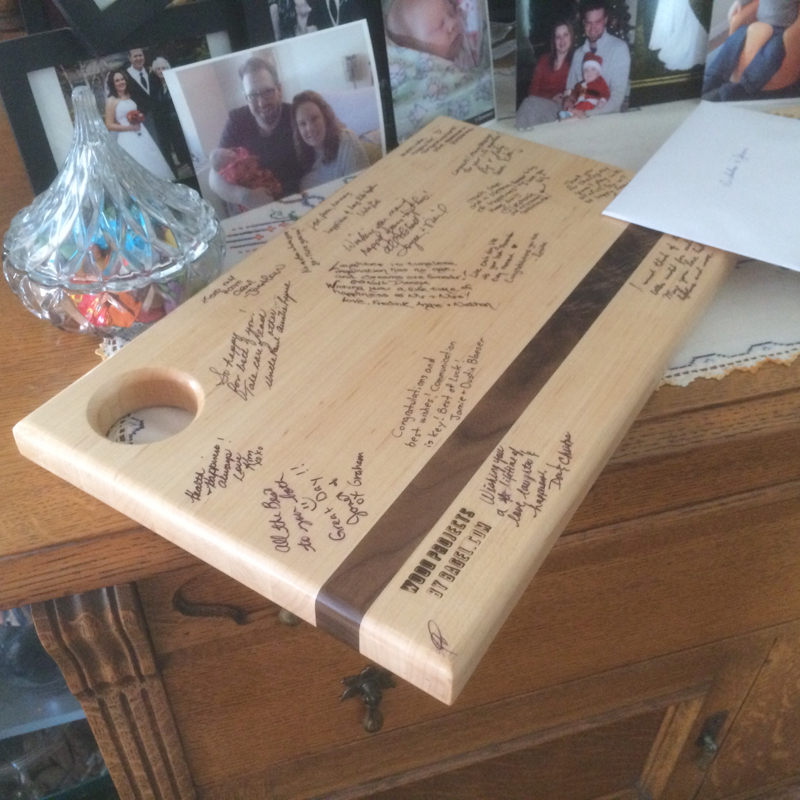

6/22/2015 Breakfast Bowls - Wedding GiftMy youngest sister just got married to her husband a couple of weeks ago so I figure I can now post about their wedding gift that I made for them. I turned a set of 4 maple breakfast bowls! I laminated two 8/4 maple slabs together to make up my bowl blanks and cut them roundish on the bandsaw to make them easier to carve round on the lathe. I mounted a face plate on each one so I could rough turn the shape of each bowl bottom. I used a forstner bit to create a mortise deep enough to receive my lathe chuck. I ended up sanding the bottom to test out how high a grit I could get to and make a super smooth finish.. After I turned the bottoms of all the bowls and sanded them to around 320 grit then took the faceplate off to then carve out the inside of the bowl. I used a carbide insert carving tool to do the majority of the work on these which was an awesome experience until I ole a check of metal imbedded in one of my bowls.. You'll notice I had six bowls there.. They were made in case I made a mistake which we'll get too shortly. More sanding.. To make the bowls a reasonable size, I had to remove about half an inche off the top of the bowl once I turned them around and mounted them on the lathe chuck. I used a fine parting tool to work my way close to the center then used a fine saw to cut the remainder off.. Then I hit a chunk of metal while hollowing out the first bowl. This was super deflating and the first real lathe event I've ever had while turning! I was hoping it was a bullet or something cool but it turned out to be a screw that was hidden in the wood that wasn't seen for some reason. Good thing I'll be checking my wood with a metal detector for future projects! Look at the chunk of carbide that was taken out of my cutter! I packed up for the night.. Then went back to work with a new carbide blade. So, in hollowing out these bowls without the proper tool rest, I had a couple of mishaps while carving. I caught an edge on the carbide cutter and on two of the bowls, the mortises weren't deep enough in the bottoms and I had two come off while carving. Now that is nerve wracking and I learned to take a break for awhile and come back to the project. So I got a set of four complete and sanded to around 800 grit which was really smooth to touch. Then I applied three coats of watco butcher block oil to protect the maple. After letting them cure for three days, they were food safe and ready for delivery! This was a long post. Thanks for sticking through it with me! I have a fair bit of really cool project work coming down the pipe. Thanks for checking out my work! 6/14/2015 Congratulations Jenn & Nick!Super HUGE congratulations go out to my sister and new brother-one-law! Great wedding and I'm more than honored to have built your guest book/cutting boards! We are so excited for you both! Once these have a bunch of well wishes filling them up for the newly weds, I will add another few coats of butcher block finish on them to make them food safe. Even if they will be kept as decorative, the will still be functional! Thanks for checking out my work! A couple of YouTube videos are coming down the pipes soon and I'm scrambling to finish up a couple of commissioned projects. This is a great wedding guest book idea if any of you are interested in ordering! More importantly, I'm super proud of both Jenn & Nick and am really excited for their next chapter! |

AuthorWelcome to WoodProjectsbyBagel! Archives

March 2018

|

RSS Feed

RSS Feed